Neoprene Blend products can be used across a wide range of industry applications. Select a product category below to find out more information regarding our custom product solutions.

Materials

Neoprene Blend

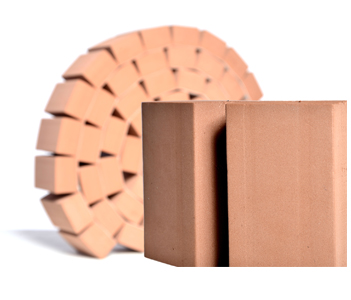

Neoprene Blend

Neoprene Blend offers the best characteristics of both materials in terms of performance and price.

Blend offers oil and petro-chemical resistance as well as offering excellent weatherproofing due to its resistance to ageing, UV, ozone and oxidation. This material provides an excellent seal under compression as well as thermal conductivity and NVH solution. At Ramsay we stock Neoprene EPDM Blend sponge buns. This allows us to offer our customers thicknesses of between 2mm – 58mm, if you are interested in Our Capabilities, please click the link. We also stock a variety of density’s and colours.

Ramsay supply a wide range of plain or adhesive backed Neoprene EPDM Blend sponge Die Cut Gaskets, Foam Tapes and Fabrication & Assembly . A majority of our Neoprene EPDM Blend products are supplied to Automotive and Mass Transit industries. This is due to Neoprene EPDM Blends material properties and range of solutions it provides, in relation to resistance to ageing, UV, ozone and oxidation. It is also a marginally more cost effective material compared to other closed cell sponges.

Material Properties

- Good Sealing properties (air, dust and water migration)

- Excellent UV & Ozone resistance

- Excellent Chemical resistance

- Outstanding ageing

- Flexible and good recovery

At Ramsay we only use materials from industry approved suppliers. In partnership with our supply partners Nitto, Recticel, Armacell, Sekisui, Avery Dennison, 3M and Zotefoams we are able to offer a wide range of high performance sponge, foams, fabrics and rubber materials. Consequently this enables us to achieve customer specification and manufacture high-quality products.

| Grade | Cellular Structure | Temperature Range | Density Range/Weight | Thickness Available | Colours Available | Technical Specificiation |

|---|---|---|---|---|---|---|

| R252/5 Neoprene Blend | Closed Cell | -40°C – +93°C | 96kg | 1mm – 58mm | Black, Grey & Brown | Download Data Sheet R252/5 Neoprene Blend |

| R252/8 Neoprene Blend | Closed Cell | -40°C – +80°C | 110kg | 1mm – 43mm | Black | Download Data Sheet R252/8 Neoprene Blend |

Neoprene Blend Samples

Ramsay Rubber have the capability to manufacture custom made Neoprene Blend samples to support project development. If there are several materials under consideration, we would be happy to provide you with a sample pack, which have a range of open cell, semi closed cell, closed cell and solid rubber materials.

Our Guaranteed Service

Our products are supplied in a condition of supply that complement our customer’s process/assembly requirements, with product development and technical support from our project management team with full APQP, FMEA planning and PPAP approval.

If you require additional information Please feel free to get in touch, to speak with one of our team of experts online, via e-mail enquires@ramsayrubber.com or call us on +44 (0) 1902 407150 alternatively you could simply fill out our online contact form. We look forward to hearing from you.

For industry insights, follow us on LinkedIn.

Do you have any questions?

Call us to speak with a member of our team:

+44 (0) 1902 407150

Alternatively you can email us

enquiries@ramsayrubber.com