UK Industry Leader

Of cellular solutions

Global Accreditation

IATF16949 & ISO14001

Experience of

Over 50 years

- Request a Quote

UK Industry Leader

Of cellular solutions

Global Accreditation

IATF16949 & ISO14001

Experience of

Over 50 years

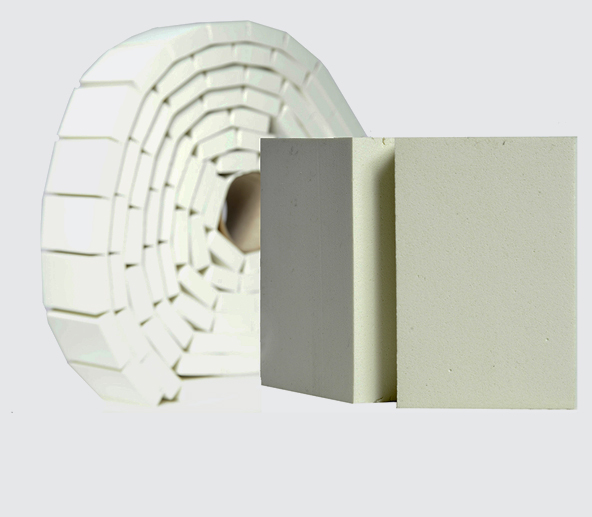

EPDM (ethylene propylene diene monomer) has become a staple material used for various applications across numerous industries with a $3.6 billion global market value (2022).

The increasing use of EPDM polymers in blended products continues to drive its commercial usage worldwide, but does it provide the ideal solution for your requirements? In this blog, we’ll provide an overview of EPDM across its types, applications, and products alongside the multiple industries that use it.

EPDM rubber provides a watertight seal with excellent weatherproofing properties that include:

EPDM rubber also provides a thermal conductive and NVH (Noise, vibration, and harshness) solution with a shore hardness of 65° ± 5° and a smooth finish on both sides.

On the other hand, EPDM sponge has similar and different properties to EPDM rubber. Unlike the dense weatherproofing of EPDM rubber, EPDM sponge provides a soft closed-cell structure that absorbs sounds and provides an ideal NVH and acoustic solution.

However, with the same material properties as EPDM rubber, EPDM sponge is also resistant to moisture ingress alongside preventing chemical-induced degradation. This quality makes EPDM sponge an excellent sealing solution while incredibly lightweight, with self-extinguishing and acoustic characteristics. You can also get recycled EPDM produced by blending former EPDM rubber with fresh EPDM or other materials.

A versatile material with both rubber and sponge capabilities, EPDM can support numerous applications for various industries. Some of these EPDM applications involve the following industries:

Due to its incredibly weather-resistant properties, EPDM is ideal for roofing and construction applications, offering long-term protection against leaks and environmental elements. For example, EPDM sponge plain washers offer excellent fixing and fastenings for various exterior components for buildings with cladding.

EPDM applies perfectly to the automotive industry for its reliable performance and sealing integrity. From EPDM rubber applications across engine gaskets, coolant hoses, and door/window seals to EPDM sponge applications in roof systems providing an excellent water ingress sealant, the automotive industry is teaming with applications perfect for the properties of EPDM.

Similar to the automotive industry, you will find EPDM applications applied in the commercial vehicle sector. EPDM sponge is used for door systems and interior cabins to provide NVH resistance and seals against water and dust. EPDM rubber plain pads can also offer an NVH solution for trailer systems.

We also see EPDM utilised in standard industrial applications, such as boiler units, with EPDM sponge supplying anti-rattle and void fill solutions.

Due to its water resistance, the HVAC and plumbing industry also utilises EPDM for various gaskets and seals in systems and installations. Preventing leaks is an essential aspect of this industry, with EPDM supporting this cause with components that can maintain tight seals and prevent leaks in fitting, pipes and ductwork.

For example, EPDM sponge works as an impressive adhesive gasket inside an HVAC vent to provide a sealant against water and dust alongside EPDM and polyethene foam as adhesive taping for ducting.

Cords and wiring in the technology and electrical sectors also require EPDM properties, with solid EPDM providing sealing and air filtration for parameter seals.

Dividing EPDM into rubber and sponge, let’s take a look at a selection of EPDM products available:

Capabilities – Plain, self-adhesive, double-sided adhesive, kiss cut and perforated

Thicknesses – 1-10mm

Capabilities – Plain, self-adhesive, double-sided adhesive, kiss cut and perforated

Thicknesses - 1-64mm

Capabilities – Plain, self-adhesive, double-sided and kiss cut

Thicknesses – 1-10mm

Capabilities – Plain, self-adhesive, double-sided and kiss cut

Thicknesses - 1-64mm

Capabilities – Plain, self-adhesive, double-sided and kiss cut

Thicknesses – 1-10mm

Capabilities – Plain, self-adhesive, double-sided and kiss cut (on a roll)

Thicknesses - 1-64mm

Capabilities – Plain, self-adhesive, double-sided adhesive, kiss cut and perforated

Thicknesses – 1-10mm

Capabilities – Plain, self-adhesive, double-sided adhesive, kiss cut and perforated

Thicknesses - 1-64mm

Diameter – 2- 25mm

Lengths (Dependent on diameter) – 100mm-25 meters

Diameter – 2- 25mm

Lengths (Dependent on diameter) – 100mm-25 meters

Capabilities – Plain, self-adhesive

and double-sided adhesive rolls

Thicknesses – 1-64mm

Widths – 100mm-1 meter

Lengths – 5-20 meters

Capabilities – Self-adhesive and

double-sided adhesive

Thicknesses – 1-64mm

Widths – 5-50mm

Lengths – 1-10 meters

Capabilities – Plain, self-adhesive

and double-sided adhesive rolls

Thicknesses – 1-64mm

Widths – 500mm-2 meters

Various applications for these EPDM products include automotive interior cabins, ventilation ducting systems, lighting systems, automotive roof rails, touchscreen displays and more. With material slitting capabilities, EPDM products are available in a custom range of sizes across thickness, width, and length, depending on the application. Plus, all EPDM products are available individually with perforations and creases to support folding or creating a 3D product.

At Ramsey Cellular Sealing Solutions, we provide numerous EPDM products with customisable options to suit all applications and purposes. All our EPDM products are registered with IMDS and accredited with IAFT 16949:2016, ISO 19001:2015 and ISO 14001:2015 certification to ensure we meet the highest standards expected from bespoke EPDM solutions.

Get in touch today for more information about how our EPDM products can support your requirements.

Please feel free to get in touch, to speak with one of our team of experts or simply fill out our online contact form below. We look forward to hearing from you.

Get In Touch

Ramsay Rubber & Plastics Limited

Vulcan Road, Bilston

West Midlands WV14 7HT

T +44 (0) 1902 407150

F +44 (0) 1902 407160